Why the |

|

NEW FOR 1994 – Arctic Cat Plastic Skis Engineered, tested, and perfected exclusively by Arctic. These high impact plastic skis delivered excellent performance. Each ski is a full 6 pounds lighter than traditional steel skis. (Not accurate, each plastic ski is only 3 ¼ lb lighter, not 6 lbs.) That adds up to performance and response. Plastic Skis kit - 0638-416 - $299.95. “Finding A Cure” A minor glitch has surfaced regarding the ultra trick and lightweight plastic composite skis found on the ZRT 800, ZRT 600, ZR 440. An error in how the wear bars mate to the ski bottom is causing some bars to not fully “seat”. The problem is occurring at the front of the bar where it should retreat up into a notch located on the ski. (There was no notch in the 1994 or 95 skis so none of the bars could seat.) In reality, the problem is a rather common occurrence. Other ski makers have had similar problems with plastic skis and wear bar mating for some time. (Name one other ski that had this problem.) Fortunately our sources say the fix is quick and easy. Simply loosen the nuts, apply heat at the right locations and bend the end of the wear bar into its new home. With the right tools, weekend motorheads can cure the problem in minutes. If you’re not up to the task, bring your scoot to your friendly Cat dealer and he’ll have you back on the trail in time. New Cat owners should check the mate between ski and wear bar on the light, tight and just so right factory issue composite skis.

|

Service Bulletin

Model: ZRT 600 • 800 - ZR440

Subject: Ski Drag Modification

Date: December 1, 1994

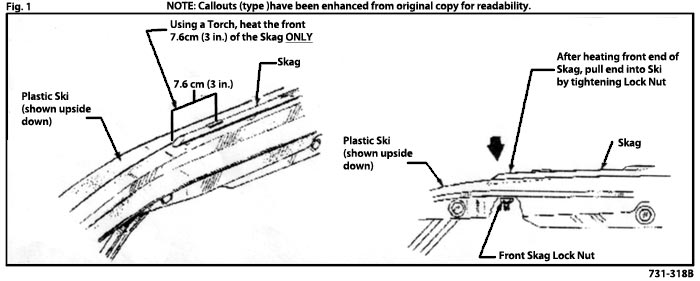

CONDITION: The front end of the ski skag may catch on stationary objects which could result in a loss of control or A-arm and front end damage. SOLUTION: If the snowmobile has already been set-up, tip the snowmobile on its side; then working on the upper ski, loosen the front skag lock nut until there is approximately 1/8 inch clearance between the bottom of the skag and the ski bottom. Using either a propane torch or a gas welder with a small tip, preheat the front 3 inches of the skag. Move the torch back and forth on the skag heating this 3 inch area evenly and directing the flame onto the skag and not the ski. Continue to heat the skag until the 3 inch area is starting to give off a slight smoke; then quickly tighten the front skag lock nut and draw the front of the skag into the plastic ski bottom until ½ of the diameter of the skag end is imbedded in the ski bottom. CAUTION Using a large flat blade screwdriver, remove the excess melted plastic from around the end of the skag and allow to cool. Repeat the same procedure on the opposite side. NOTE: If the skis have not been installed, perform this procedure with the ski held upside down in a vise.

WARRANTY: A group warranty claim of up to 10 serial numbers will be accepted. Write 95-07 in the failure code section of the warranty claim. A labor allowance of 0.4 hours will be paid per snowmobile. NOTE: If any of the affected snowmobiles have been delivered, please contact each owner and have them bring their snowmobile in for this very important modification. Arctco,Inc. PO Box 810, 600 South Brooks Ave, Thief River Falls, MN, 218-681-8558

|

| Home |

Arctic Cat Wear Rod

Application Chart | Ski Savers Chart | Trail Grabbers Chart |

| Site Map |

Copyright © 1999-2016 Bergstrom Skegs, Inc.

All

rights reserved.